Renewing Our Planet’s Greatest Resource

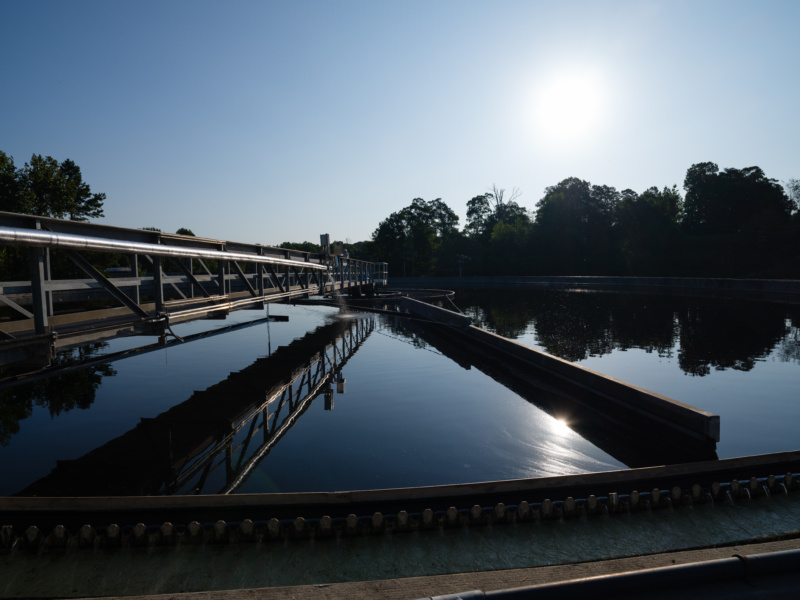

We have a responsibility to our customers, our community and our environment. And we don’t take this responsibility lightly. By elevating the quality of our waterways, we sustain and enhance our area’s quality of life through responsible and sustainable practices.

Biosolids

By using by-products from our treatment process to create biosolids, we create a natural and environmentally-sound fertilizer for local farmers in Anderson, Greenville, Laurens, and Spartanburg counties.

The ReWa Biosolids Program uses state-of-the-art equipment to reclaim safe, organic material from the over 40 million gallons of wastewater that we clean every day.

Oyster Shells

Did you know the shells of oysters shared over a seafood dinner can be re-used to breed more oysters? It’s important we collect and re-introduce discarded shells back into the ocean to keep our state’s oyster population thriving because oysters help contribute to better water quality by filtering water from harmful irritants.

An adult oyster can filter as much as 50 gallons of water a day. That’s why we’ve joined a statewide effort to keep South Carolina's oyster beds alive by establishing an Oyster Shell Recycling program. Our program encourages local restaurants and individuals to donate discarded oyster shells to ReWa to be returned to the coast. You can find our drop off bin past our administration building on Mauldin Road.

Going Solar

We believe actions speak louder than words, which is why we work hard to ensure that our day-to-day operations reflect our commitment to responsible and sustainable management practices.

As an example, we’re continually striving to incorporate solar power into our wastewater treatment processes. Currently, three of our facilities utilize solar power.

Solar energy can:

- Reduce Air Pollution

- Reduce Water Usage

- Reduce Dependence on Non-Renewable Energy Sources

- Improve Humanity’s Health in the Long-Run

- Help Fight Climate Change